Cyclone Filtration in Roomba S9 Base Station

Possible? Yes

Chance of Failure? Medium

STLs and Fusion 360 are linked below.

Project Intro:

Objective:

Design and 3D print a replacement to the classic iRobot Roomba Station Bags. Never before have I designed a cyclone filtration solution, which required a lot of research.

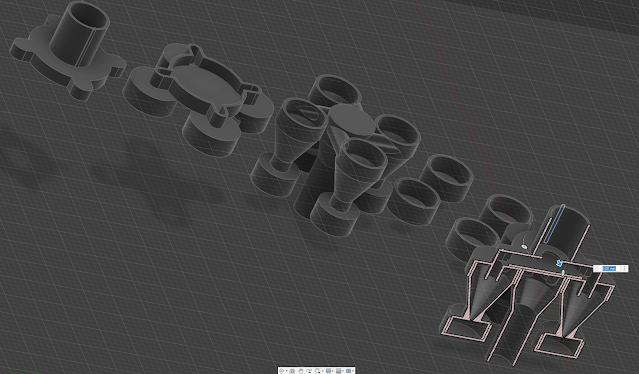

Design:

Cyclone Testing:

This time, we are testing varying particle sizes and different aperture sizes. Again, very surprised by how well it worked! I connected these to my Dyson V12 for consistent, reliable suction in particle testing.

After 40+ hours of printing and trial-and-error testing, I was ready to begin the final design as the first proof of concept.

Findings:

There is a scientific method to approaching this, and a complete understanding of several external factors would need to be known to render the best possible cyclone. Factors such as suction power and particle type/size/weight" must be mostly consistent. However, you can get away with "Most" filtration with a moderate to high suction power, and limiters can be installed to ensure what enters the cyclone is within the expected size.

Final Design:

4 days of printing. STLs, and Fusion 360 Models here:

Pre-Cyclone Filter:

A 0.1 MM aperture mesh is installed as a pre-cyclone filter melted into the mesh, easy to find on Amazon. Be aware, very sharp!

We have our complete proof of concept. Does it fit?

Testing our first proof of concept:

Wrapup Summary:

Feasible? Yes

This proof of concept shows results; however, if I had more time, I would have taken a more scientific approach and sealed the product better.

I would say it is likely that iRobot will come out with a Cyclone Filtration Adapter as it would earn revenue for them and can still make them $$$ on HEPA Filters.

In this day and age, the concept is well-proven; it's just a matter of who can design, produce, and bring it to market.

A 3D printer will likely bring this to market before an injection molded solution.

Good Luck!

Comments

Post a Comment